Welcome

Personalised

Surgical

Innovation

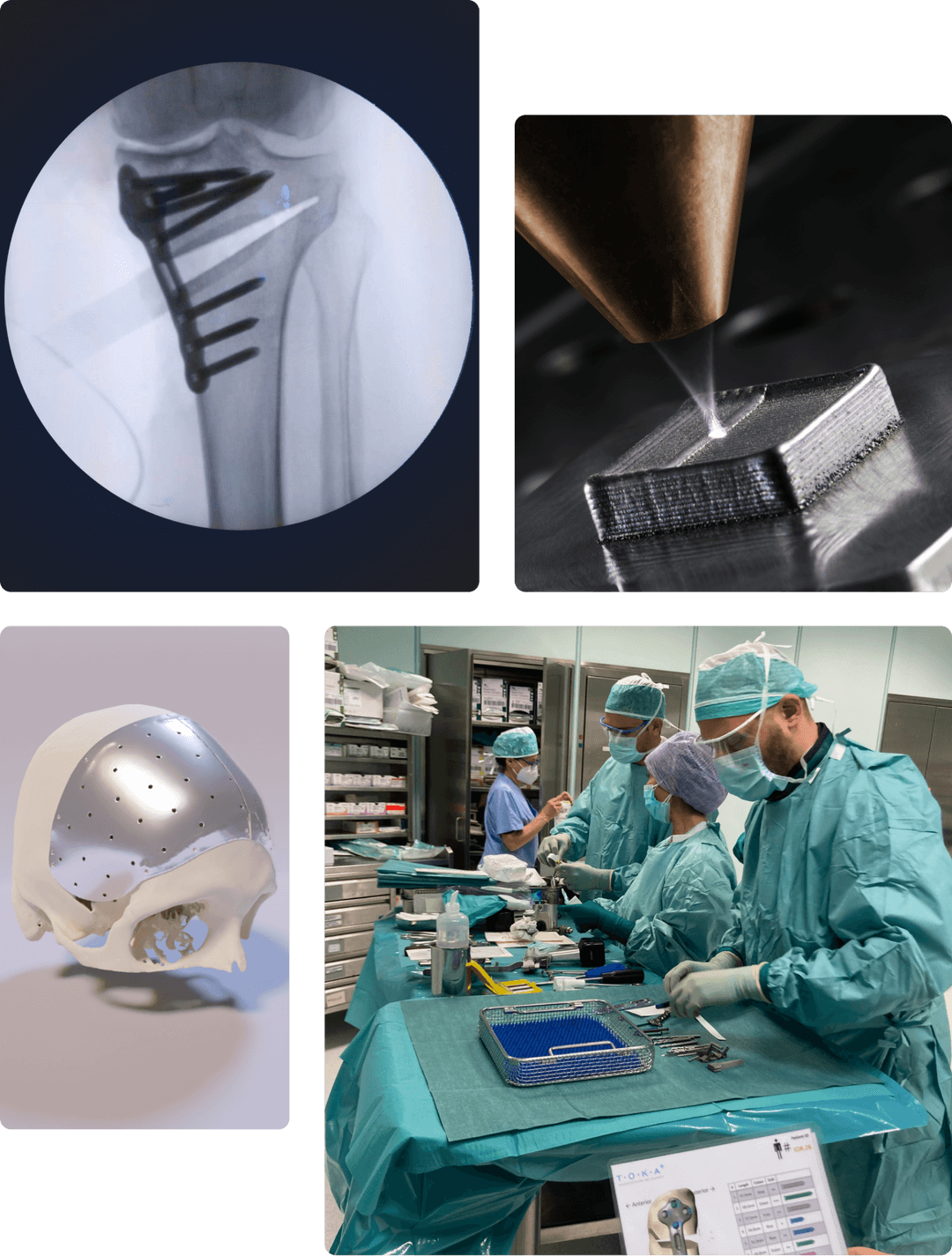

At Orthoscape, we are at the forefront of additive manufacturing for medical applications. We offer patient-specific surgical treatments with our flagship product; the Tailored Osteotomy Knee Alignment (TOKA®) system.

Our Products

The Orthoscape Ecosystem

TOKA

Additively manufactured Patient-specific knee treatments.

OrthoCMF

Design & manufacture of cranial maxillo-facial implants.

Artifex

Dedicated osteotomy pre-operative planning software.

Orthoscape Connect

Upload, review, manage & visualise surgeries in 3D.

What we do

Cutting edge medical device design & additive manufacturing

Medical Grade 3D Printed Materials

SLS, FDM, Photo-curable resins

Segmentation & 3D Modelling

Expert in-house medical implant designs

Research based Innovation

University & orthopaedic institute backed R&D

Medical Device Software Development

Transforming surgical treatment for the benefit of healthcare providers

Experts in Finishes

Customised to each device & application

Quality Approved Production Process

ISO:13485 Certifed patented technology

Blog